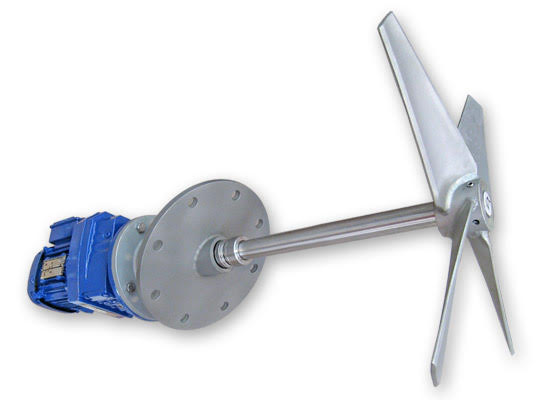

The VinFoil Mixer sets the standard for efficiency in cold stabilization and mixing for large volume tanks. Cold stabilization is achieved three times faster than the pump method with a total average energy savings of over 80%.

The VinFoil Mixer’s impeller is engineered to maximize flow and minimize turbulence. The impeller blades are slim at the tip, where the speed is highest, and wide at the base where speed is lowest, allowing all available energy to be transferred into a pure axial flow pattern in the tank. The twist in the blades is computer proportioned to eliminate turbulence.

Try Before You Buy

The VinFoil Mixer offers superior advantages but don’t take our word for it, try it for yourself. Our custom built trial unit is designed to fit any standard tank door size so you can compare the VinFoil Mixer for yourself and see the difference.

__________________________________________________________________________

For More Information on Vinfoil

Brochure: View for an overview of Vinfoil, the technology and configurations : 2023 Vinfoil Brochure (Click here to view in Spanish)

Application Sheets: View for more information on VinFoil’s capabilities.

- Cold stabilization (Spanish Version)

- Solids feed to centrifuges (Spanish Version)

- Oak extraction (Spanish Version)

- White wine primary fermentation Control (Spanish Version)

- General blending / temperature control (Spanish Version)

- Whiskey blending (Spanish Version)

Articles:

- Vinfoil Wine Tank Mixers Improve Winemaking Processes, Save Energy and Labor Costs, and Offer Remote Monitoring Capabilities

- Vinfoil Mixers for Blending Bentonite During the Winemaking Process

- Optimizing Bentonite Fining in Winemaking: Effective Mixing Methods and the Benefits of the Vinfoil Mixer

- Enhancing Oak Extraction with Vinfoil Tank Mixers

- Optimizing White Wine Fermentation and Solids Feeds with Vinfoil Mixers

- Revolutionizing Whiskey Production with Vinfoil Tank Mixers

- What is a Vinfoil Mixer and Why do Winemakers Need One?

To learn more about VinFoil mixers, please view our video.

VinFoil Tank Mixer

VinFoil Tank Mixer