March 22, 2022

What Is a Vinfoil Mixer and Why Do Winemakers Need One?

Mixing is a crucial part of the winemaking process, and BevZero provides the equipment needed for success.

Winemakers know that the secret to a pristine final product is in the gritty details. For this, mixing, agitating, or blending is a crucial step. Year after year, winemakers want to increase quality and consistency, and the technology needed to do so must mirror these same ambitions. CEM International (CEM) has developed a mixing solution using the Vinfoil Mixer to achieve these desired results.

Wine Mixing Sub-Optimal Options

The intent of mixing in wine tanks is to optimally disperse solids for tannin, pigment, and mouthfeel – from white wines in steel tanks to high-tannic reds in oak. Control over this process is important to reduce over-extraction and oxidation that could lead to bottle variance and low quality.

The most common mixers are high velocity. They can rotate at speeds of 1800 RPMs, a force that can lead to violent, unstable, and undesirable effects that include frothing, overworking of added solids, oxidization, and degradation.

Pumps offer a simple method to mix, but in reality, pumps are extremely inefficient. As a result, they can lead to poor circulation in large tanks and “dead zones” where agitating is non-existent in part of the tanks. In addition, pumps can be expensive, requiring time, energy, and labor.

The Vinfoil Mixer Solution

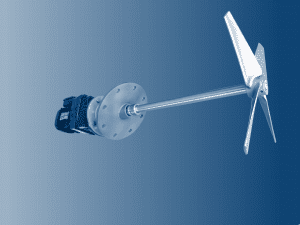

The Vinfoil Mixer from BevZero provides a solution for these issues. It has a sleek and efficient design capable of thoroughly mixing any size tank up to 300,000 tons. In addition, it rotates slowly at 277 RPMs providing a gentler blend for control over multiple stages of fermentation.

The benefits include:

- Consistent quality: The controlled blending allows programming for multiple tanks allowing winemakers to manage fermentation rates and find more precision in processing times and temperatures. Suitable for a variety of mixing needs including cold stabilization, temperature striation, oak extraction, white wine fermentation, centrifuge feed tanks and more.

- Time Saved: Although gentle, Vinfoil is still powerful. Its blending improves flow rate, and its efficiency allows for less rotation while still providing a quality product but in a shorter amount of time. This can lead to quicker bottling times and an increase in tank turnover.

- Reduced Energy Consumption: Time saved equals reduced energy consumption. The average time of five turnovers required for mainstream agitators is done in a ten-hour timeframe at high-velocity speeds. The Vinfoil turns an entire tank over five times typically in under one hour. The uniformity of solids allows those solids to be fed into the centrifuge steadily, minimizing technical maintenance.

- Money Saved: Less energy expended with a more efficient and cleaner process will ultimately save money in labor, time, and energy costs. Turning over tanks and bottling more quickly will allow for more space to increase supply.

- Desired Final Product: Every winemaker knows how they like their final bottled product. With more control over solid diffusion and a controlled and gentler process, tannin structure from either pomace or oak can be more controlled, as will pigment. Vintners can manage primary fermentation flavors and lees aging for the final desired effect for white wines.

The Vinfoil Mixer can align with wineries’ growing needs of saving money, time, and energy, while assisting ambitious winemakers in consistently producing their desired final product.

If your team is interested in learning more about the Vinfoil Mixer, please contact us.