April 2, 2023

Equipment Spotlight: Vinfoil, the Energy-Saving Wine Tank Mixer

Vinfoil Wine Tank Mixers Improve Winemaking Processes, Save Energy and Labor Costs, and Offer Remote Monitoring Capabilities

The mechanical mixing of a wine tank can have a dramatic effect on wine consistency, quality, and taste. BevZero’s Vinfoil wine tank mixers, custom-designed precisely for each tank, eliminate temperature striation throughout the vessel, thus ensuring a controllable, consistent product.

During primary fermentation and cold stabilization, the rate of controlled cooling provided by Vinfoil tank mixing is increased by reducing product residence time to complete required wine treatment, resulting in faster process outcomes with increased tank turnover rates. The faster processing time provides a reduction in energy usage, and thus a cost savings. Additionally, since the Vinfoil mixers are designed precisely for each tank, there is no moving from tank to tank, reducing labor and worker injuries. The Vinfoil mixer can be easily integrated to operate in conjunction with related winery automation systems and allows for remote monitoring capabilities.

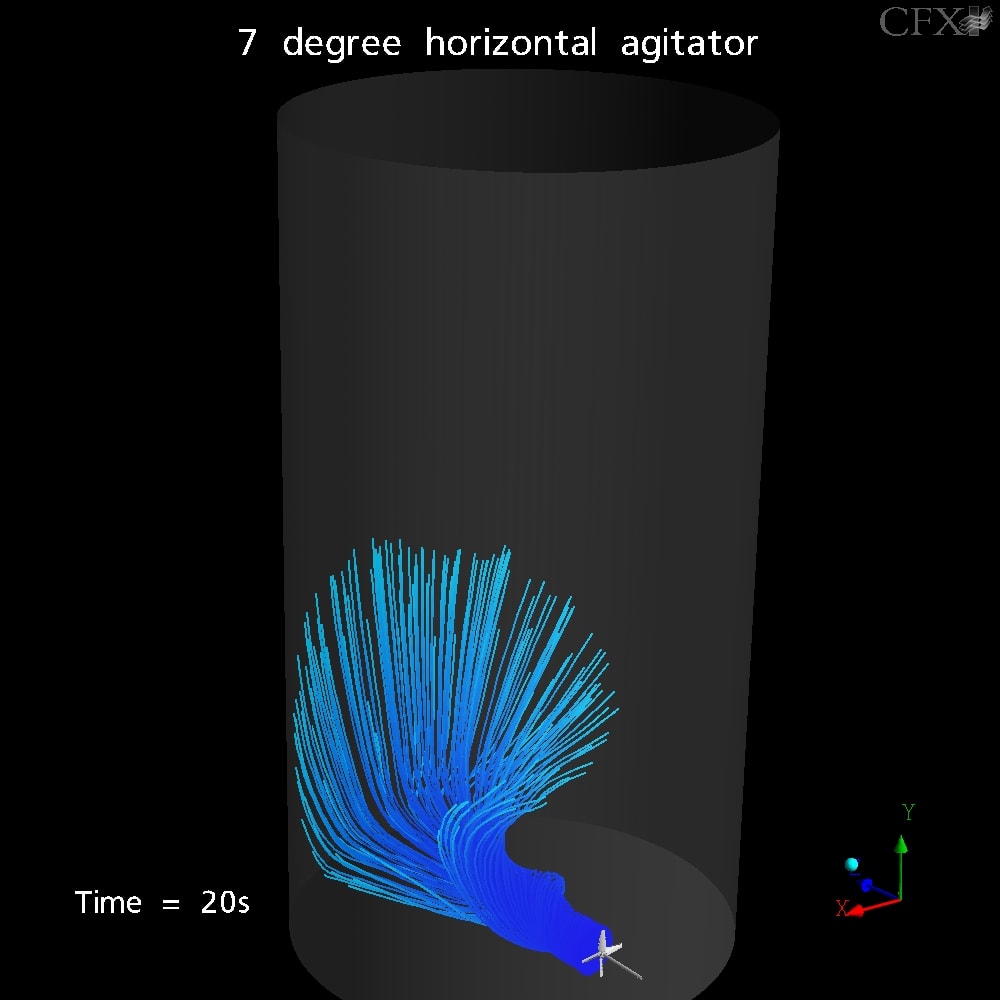

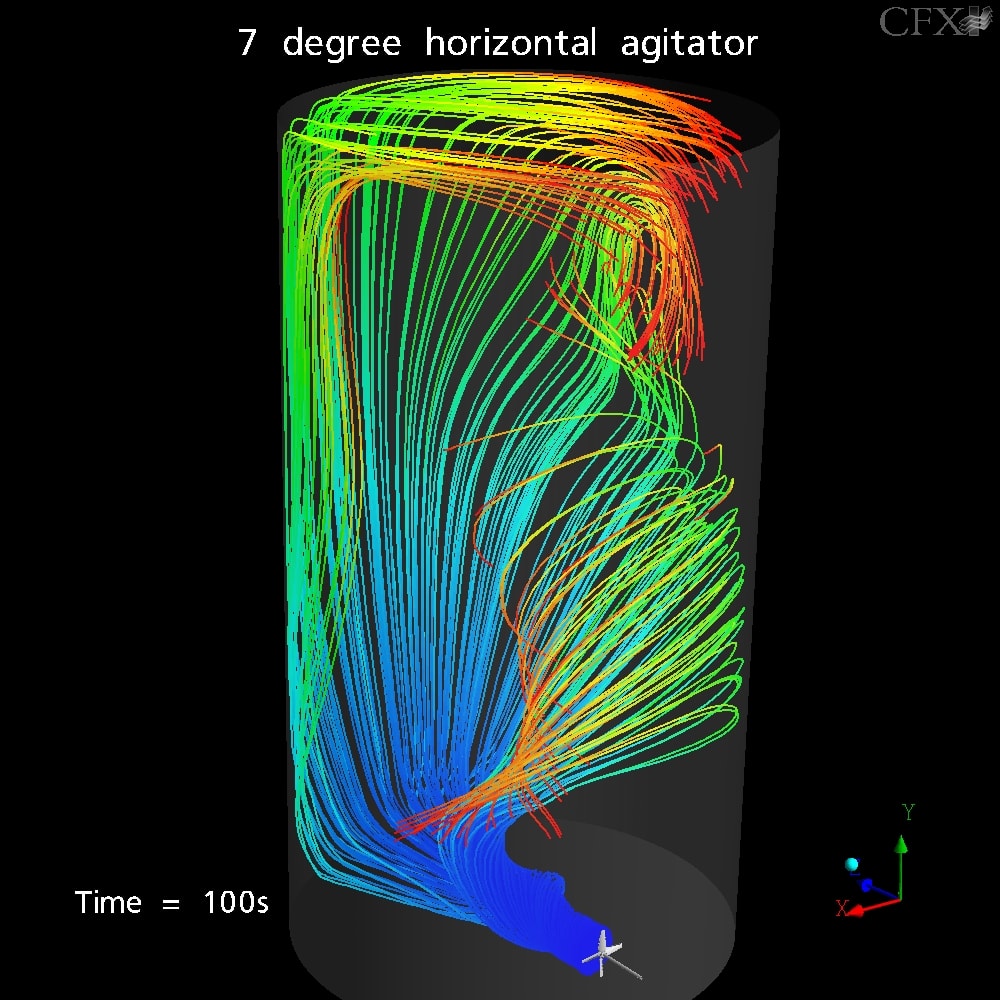

The Vinfoil is designed specifically for the wine industry to create the right flow patterns by generating maximum exit velocities, and transferring maximum axial flow patterns into the tank with minimum turbulence. It is a low shear device, utilizing less power requirements than any other impeller, and as a result, Vinfoil provides a thorough yet gentle mixing of wine. In comparison, the high speed, high shear centrifugal pump-over method is harsh on the wine, damaging the wine’s structure and resulting in negative effects on the sensory elements of the wine. The pump-over method can also leave untouched dead zones.

The Vinfoil tank mixer can be used for a variety of winemaking applications, including cold stabilization, oak extraction, general blending, and temperature control.

Using the right mixer performs for the winemaker. With Vinfoil, you can expect:

- Gentle and consistent blending with no tank dead zones

- Low oxygen pick-up

- Significantly faster homogenization and better plant utilization

- Improved wine structure and better mouth feel during primary fermentation

- Can be integrated to operate in conjunction with related winemaking equipment and automated systems

- Lower capital and operating cost

- No water use

- Energy and labor savings

How does it work?

The unique geometry of the Vinfoil Mixer’s impeller was specifically engineered to maximize flow and minimize turbulence. The impeller blades are slim at the tip, where the speed is highest, and wide at the base, where speed is lowest, allowing all available energy to be transferred into a pure axial flow pattern in the tank. The twist in the blades is carefully proportioned to avoid any turbulence. The mixer’s blades provide powerful tsunami-like waves, which can turn the entire tank of wine over in a fraction of the time of other methods. Less time processing means less energy used.

The combination of the hydro-dynamic impeller and the lowest kilowatt motor requirement in its class makes the Vinfoil Mixer the most efficient and gentlest wine tank mixing solution on the market.

Every Vinfoil mixer is specifically designed to meet our customers’ process requirements, whether simple blending, solids suspension, gas dispersion or a complex reaction. The goal is to provide effective and reliable mixing at lower power consumption to ensure optimum efficiency.

Energy and Labor Savings

State-of-the-art process calculation and modeling tools are used in the custom development of each mixer, and combined with decades of design experience, each mixer is custom-designed to the customers’ tank and specifications. Once the Vinfoil mixers are installed and configured to the plant control system, operation is very simple with one easy button. This means no set-up time, and no moving equipment around, reducing labor costs and worker injuries. Vinfoil Mixers are compatible with any automation system, making operation even easier. Additional key facts include:

- Blend times improved by 90%

- Cold stabilization achieved 3 times faster

- Complete tank homogenization in a fraction of the time

- Increased predictability of wine treatment, no need to repeat

- Energy savings of 80% or more

- More time saved allows for more cellar operations

Configuration Options

Vinfoil Impeller options:

- VINFOIL-RTF4 suitable for gentle blending. Top or side entry mounts.

- VINFOIL-P suitable for additive mixing. Top entry mount.

Vinfoil Mixer Configurations include:

- Wide size range from small boutique wineries to large scale operation

- Top, side, and bottom tank entry points, and portable tank mixers

- Retractable mixer to conduct maintenance with full tank

- Explosion protected motor available

- Various seal options (mechanical, lip, hydraulic, etc.)

- Special mixer for operating under high pressure (Charmat method)

Compatible with any Automation System

- Capable of being networked for remote monitoring, alarming, and process control

- Create timed mixing schedules

- Activate mixing based upon temperature stratification in tank

- Automate and improve cold stabilization by integrating VinFoil activity with chilling settings