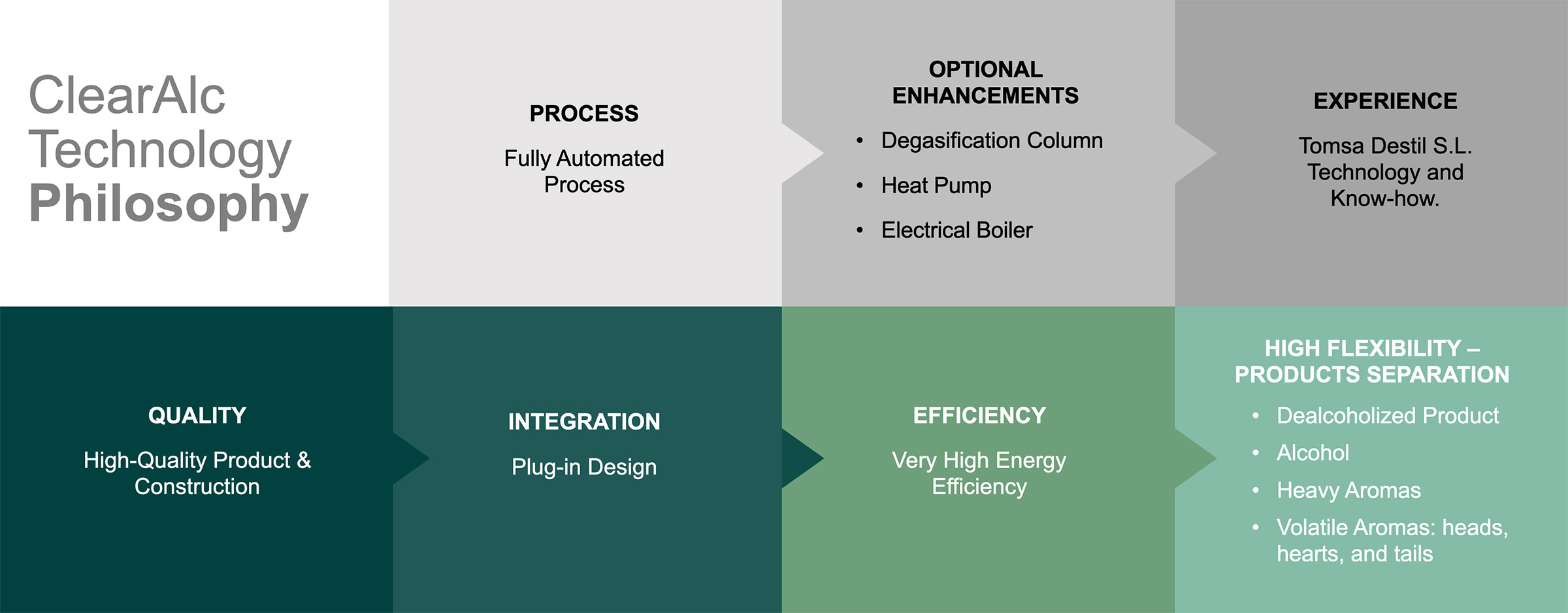

ClearAlc uses a highly energy-efficient, single pass vacuum distillation process capable of separating different volatile aromatic compounds (heads, hearts, and tails). ClearAlc is capable of dealcoholizing as desired down to 0.05% abv, and rectification of the alcohol fraction (up to 92% abv). ClearAlc offers advanced technologies to ensure sustainability with very high energy efficiency, lower maximum temperature, and minimal water use.

ClearAlc is manufactured by Tomsa Destil, a company located in Europe (Spain) with more than 170 years of experience in alcohol technology for the international market, and which controls their own supply chain.

_________________________________________________________________________________

Learn more about ClearAlc Dealcoholization Technology with these tools:

Brochure: View for an overview of ClearAlc: 2024 ClearAlc Brochure (Click here to view in Spanish)

Features and Benefits

- Dealcoholization for Wine, Spirits, and Cider.

- Model Sizes: 800 L/h to 3000 L/h

- Full Automated Single Pass Process

- High flexibility products separation

- Dealcoholize as desired down to 0.05% abv

- Rectification of the alcohol fraction (up to 92% abv).

- Extraction of heads, hearts, and tails

- Very High Energy efficiency

- Reduced Product Losses

- Minimal Water Use

- High vacuum and low temperatures

- Design according to local standards and requirements

- High quality manufacturing materials and construction

- Self supported skid mounted units

- Integrated MCC & Control panels

- Fully automated system with remote data acquisition

- Optional Enhancements:

- Degasification Column

- Heat Pump

- Electrical Boiler

- Spare parts / O&M services available

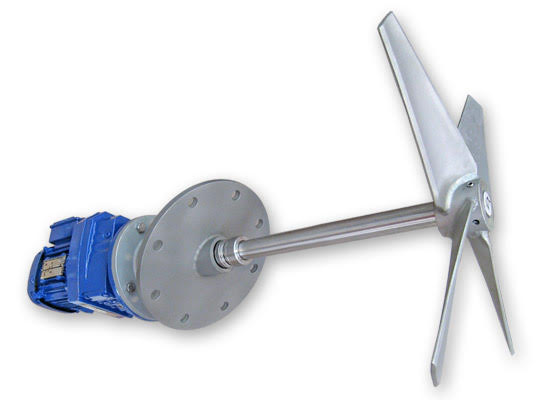

BevZero not only distributes but utilizes the vacuum distillation method for its dealcoholization processing. This method is ideal for low and no alcohol products because it can remove alcohol gently without loss of aroma or flavor. This technology combines a large surface contact area, low temperature, and minimal residence time to avoid any thermal damage or stress to the wine. To learn more about this method, view our multiple blogs.

BevZero also provides a dealcoholization service. For more information click here.

Stay ahead in a rapidly changing beverage landscape. Subscribe to BevZero Bulletin, our quarterly breakdown of the critical issues and opportunities for the beverage sector.

ClearAlc Dealcoholization Technology

ClearAlc Dealcoholization Technology