October 7, 2022

Working with BevZero to Hit the “Sweet Spot” in Winemaking

The Problem

In many of the world’s grape-growing areas (e.g. California, Chile, Australia, Southern France, South Africa, Spain, etc.) increasingly hotter climate conditions have driven sugar and alcohol levels several points higher than are desirable for winemakers.

The Consequences

Higher sugar and alcohol levels can lead to stuck fermentations, over extraction of undesirable grape components near the end of fermentation, and a muting effect on the aroma and flavor of the wine that is found to be undesirable by consumers worldwide.

BevZero’s Answer

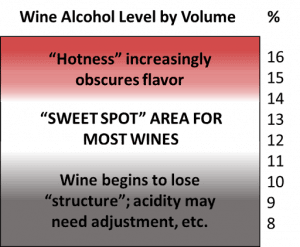

By precisely adjusting your wine’s alcohol content you can achieve harmony and balance with all the other components of the wine (the “sweet spot”), in a process completely controlled by the winemaker. In a Sweet Spotting Consultation, the winemaker visits BevZero where they taste a series of wines starting with the original product and working through increments of slightly adjusted alcohol levels to determine their desired final product.

The secret to achieving the sweet spot is BevZero’s gentle yet precise method of alcohol removal which uses a unique process of thin film vacuum distillation with a low temperature and short residence time. This highly selective separation process avoids thermal damage or stress to the wine. The process consists of five simple steps:

- BevZero receives only a small portion of the wine

- The wine’s delicate, volatile aroma compounds are captured and kept for later reintroduction to the wine

- The alcohol is removed

- The aroma compounds are put back into the wine

- The winemaker can blend the dealcoholized wine back into the original wine stock to achieve the desired alcohol level

It’s Simple!

Why Winemakers Keep BevZero in Their Toolbox

Alcohol adjustment gives winemakers control over some of their wine’s most vital characteristics. It reduces perceived heat from alcohol, which enhances consumer flavor perception. It can make wines feel brighter and increase the focus and purity of fruit by bringing alcohol levels into balance with other wine components. Being able to find tune alcohol levels during or after fermentation allows for picking decisions based on flavor development, pH, and phenolic maturity without having to pick early because of high Brix.

From the vineyard to bottling, winemakers can produce the flavor profiles they want without concern for the resulting alcohol level, which can be tuned to cater to various international markets and tax structures.

New Markets – Next-Gen Technology

Demand for low and no alcohol products has seen a surge in recent years and is expected to continue to grow rapidly over the coming decades. According to Nielsen, there was a 33% increase in the volume of low and no alcohol products through 2020. That number is expected to grow at an 11% CAGR through 2024, with especially notable growth in beer and wine. BevZero is meeting this demand with its experience, capabilities, and next-gen technology.

BevZero’s alcohol adjustment service can be used for the removal of alcohol (dealcoholization), down to 0.0% abv, while still maintaining most of the original wine’s volatile aroma compounds. BevZero’s expertise can help to develop and formulate excellent low and no products.